3D Printing: Revolutionizing Manufacturing and Prototyping

Introduction

Over the past few decades, 3D printing has emerged as a groundbreaking technology that is revolutionizing the world of manufacturing and prototyping. Also known as additive manufacturing, 3D printing enables the creation of three-dimensional objects by layering materials in a precise and controlled manner. This cutting-edge technology has the potential to reshape various industries, offering endless possibilities for innovation and customization. In this blog, we will explore how 3D printing is transforming traditional manufacturing processes and revolutionizing prototyping.

1. Rapid Prototyping

One of the most significant advantages of 3D printing is its ability to rapidly prototype new designs. Traditional prototyping methods often involve complex and time-consuming processes, such as CNC machining or injection molding, which can take weeks or even months to complete. In contrast, 3D printing allows for the quick production of physical prototypes directly from digital designs. This not only saves time but also enables designers and engineers to iterate and refine their ideas more efficiently. With 3D printing, it is possible to test multiple design variations, identify flaws, and make improvements at a much faster pace.

2. Customization and Personalization

In the traditional manufacturing paradigm, mass production often leads to standardized products with limited customization options. However, 3D printing breaks this mold by enabling highly customizable and personalized manufacturing. With the ability to fabricate objects layer by layer, 3D printers can create intricate and unique designs tailored to individual preferences and requirements. Whether it’s customized jewelry, personalized medical devices, or bespoke automotive parts, 3D printing empowers consumers and businesses alike to bring their ideas to life in ways never before possible.

3. Complexity without Compromise

Complex geometries and intricate designs have always posed challenges in traditional manufacturing processes. However, 3D printing eliminates many of these limitations. By building objects layer by layer, 3D printers can easily produce complex shapes, internal structures, and intricate details that would be difficult or even impossible to achieve using traditional methods. This newfound freedom of design allows for the creation of lightweight yet strong components, optimized for specific applications. Industries such as aerospace, automotive, and healthcare are leveraging 3D printing to develop lighter aircraft parts, efficient engine components, and patient-specific medical implants.

4. Streamlined Supply Chains

3D printing has the potential to transform supply chains by minimizing dependencies on centralized production facilities and reducing transportation costs. With traditional manufacturing, goods are often produced in one location and then shipped to various distribution centers and retailers worldwide. In contrast, 3D printing enables localized production, where products can be manufactured on-demand and closer to the point of consumption. This decentralized approach reduces the need for large inventories, eliminates transportation delays, and enables more efficient inventory management. By streamlining supply chains, 3D printing can offer significant cost savings, environmental benefits, and increased flexibility for businesses.

5. Sustainability and Waste Reduction

Another compelling aspect of 3D printing is its potential to contribute to a more sustainable manufacturing ecosystem. Traditional manufacturing processes often generate substantial waste due to subtractive manufacturing methods, where excess material is removed to shape the final product. In contrast, 3D printing is an additive process, only using the precise amount of material needed to construct an object. This leads to significant material savings and reduced waste. Additionally, 3D printing allows for the use of recyclable and bio-based materials, further minimizing the environmental impact of manufacturing.printing is reshaping industries and unlocking new possibilities for the future. As we delve further into this digital manufacturing revolution, it is exciting to envision the limitless potential that 3D printing holds for innovation, creativity, and problem-solving in the years to come.

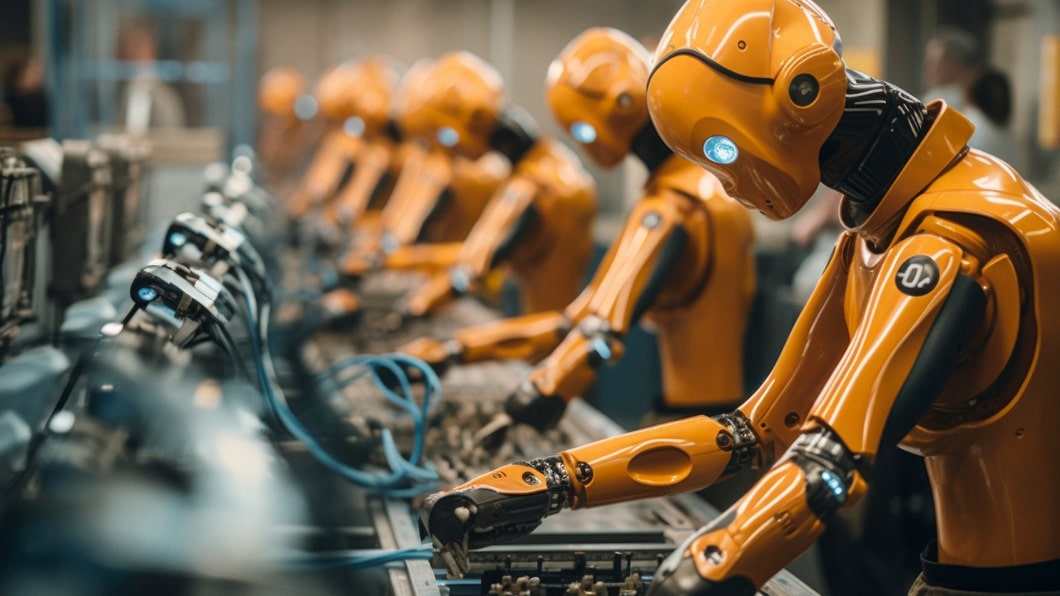

6. Accessibility and Democratization of Manufacturing

Traditionally, manufacturing complex objects required specialized tools, equipment, and expertise, making it a privilege reserved for large corporations with significant resources. However, 3D printing has democratized manufacturing by making it more accessible to individuals, small businesses, and even hobbyists. With affordable desktop 3D printers, anyone can now turn their ideas into physical objects without the need for extensive manufacturing infrastructure. This accessibility fosters a culture of innovation, empowering entrepreneurs and individuals to bring their visions to life and disrupt traditional manufacturing models.

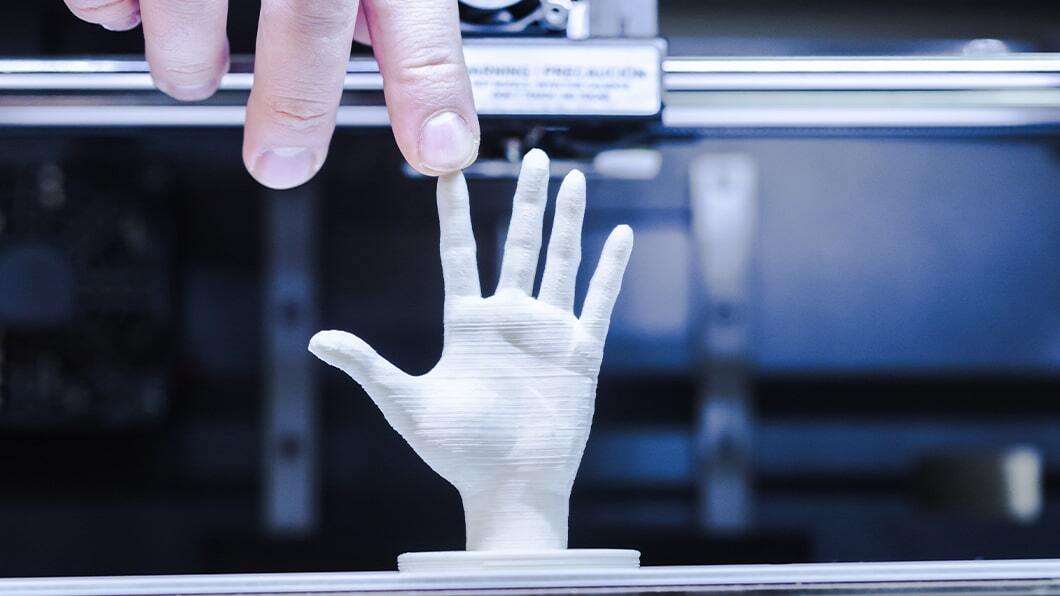

7. Medical Advancements and Bioprinting

In the field of medicine, 3D printing has opened up incredible possibilities for advancements in patient care. Customized medical implants, prosthetics, and anatomical models can now be produced with exceptional precision, tailored to individual patients’ needs. Surgeons can utilize 3D-printed models to plan complex surgeries, improving surgical outcomes and reducing risks. Furthermore, the emerging field of bioprinting holds promise for printing living tissues and organs, potentially revolutionizing transplantation and regenerative medicine. While still in its early stages, bioprinting offers hope for addressing the global organ shortage and transforming healthcare as we know it.

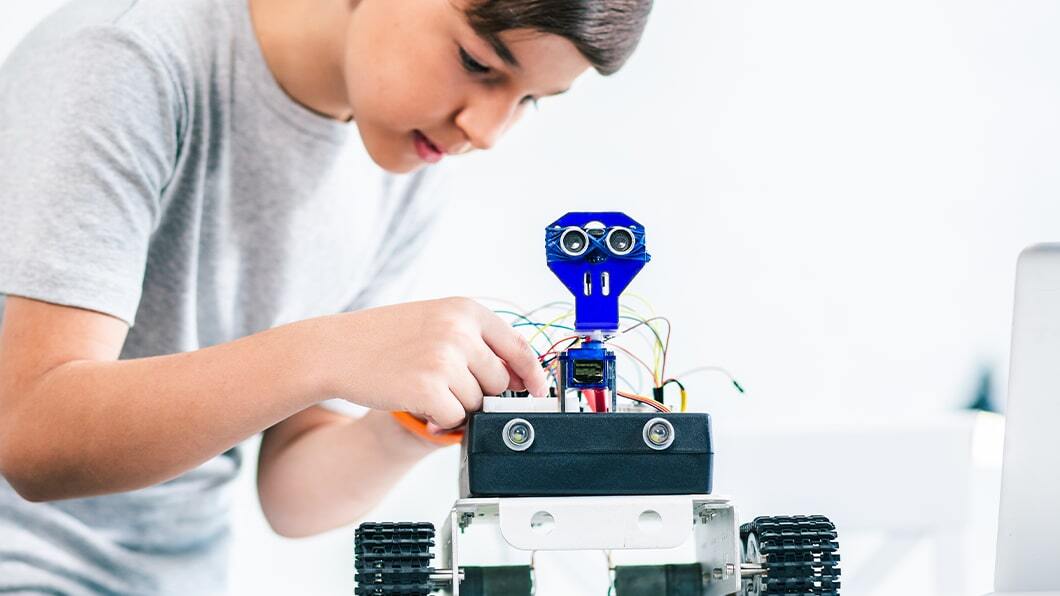

8. Education and Learning Opportunities

3D printing is becoming an invaluable tool in education, offering hands-on learning experiences and fostering creativity and critical thinking among students. By integrating 3D printing into educational curricula, students can gain practical skills in design, engineering, and problem-solving. They can create physical representations of their ideas, test concepts, and witness the transformation from digital designs to tangible objects. This immersive learning approach not only enhances engagement but also equips students with the skills required for the future workforce, where 3D printing is expected to play an increasingly significant role.

9. Exploration of New Materials and Properties

With 3D printing, materials are not limited to traditional options such as plastic, metal, or ceramic. The technology allows for the exploration and utilization of new materials with unique properties and characteristics. From conductive inks and flexible polymers to advanced composites and even living cells, 3D printing opens doors to materials that were previously challenging to work with using conventional manufacturing methods. This versatility in material selection enables the creation of innovative products with enhanced functionalities, paving the way for breakthroughs in fields like electronics, aerospace, and renewable energy.

10. Collaborative and Open-Source Innovation

The 3D printing community embraces a collaborative and open-source approach, driving innovation and knowledge sharing. Online platforms and communities provide access to a vast library of digital designs, allowing individuals to download, modify, and build upon existing models. This collaborative ecosystem fosters a spirit of innovation, where ideas and improvements can be freely shared, benefiting both individuals and industries at large. It also promotes the democratization of knowledge, enabling individuals with limited resources to leverage the collective expertise of the global 3D printing community.

3D printing is undeniably revolutionizing manufacturing and prototyping, disrupting traditional practices, and ushering in a new era of possibilities. Its ability to accelerate prototyping, enable customization, support sustainability, and foster innovation is transforming industries and empowering individuals and businesses alike. As the technology continues to advance, it holds the potential to reshape not only how we manufacture products but also how we approach problem-solving, education, healthcare, and beyond. With its profound impact and ongoing developments, 3D printing is an extraordinary tool propelling us towards a future of endless innovation and creativity. As researchers and engineers push the boundaries of 3D printing technology, we can anticipate even more remarkable advancements in the years ahead.

Imagine a future where on-demand production is the norm, with products tailored to our specific needs and preferences. Need a replacement part for a household appliance? Simply download the design and print it at home. Want a customized piece of jewelry? Design it yourself and have it printed in minutes. This level of convenience and personalization is becoming increasingly feasible thanks to 3D printing.

Moreover, 3D printing has the potential to revolutionize the manufacturing industry by significantly reducing waste. With traditional manufacturing methods, excess materials are often discarded, contributing to environmental degradation. In contrast, 3D printing allows for precise material usage, minimizing waste and promoting sustainability. Additionally, the ability to recycle and repurpose materials in 3D printing further reduces the environmental footprint of the manufacturing process.

The medical field is another area where 3D printing is making remarkable strides. From patient-specific implants to prosthetics and surgical models, the technology is enabling breakthroughs in healthcare. Surgeons can now practice complex procedures on accurate 3D-printed models, improving surgical outcomes and reducing risks. Customized implants can be designed and fabricated to precisely fit a patient’s unique anatomy, enhancing comfort and functionality. The field of bioprinting, where living tissues and organs are printed using bioink and cells, holds promise for future advancements in regenerative medicine and organ transplantation.

In addition to its practical applications, 3D printing is inspiring a new wave of creativity and innovation. Artists and designers are exploring the possibilities of the technology to create intricate sculptures, architectural models, and avant-garde fashion pieces. The ability to transform digital concepts into tangible objects has unleashed a new realm of artistic expression and craftsmanship.

As with any disruptive technology, challenges remain. Improving printing speed, expanding material options, and enhancing the resolution and accuracy of 3D printers are ongoing areas of research and development. Furthermore, the ethical implications of 3D printing, such as intellectual property concerns and the regulation of printed firearms, must be carefully addressed as the technology evolves.

In conclusion, 3D printing is revolutionizing manufacturing and prototyping in ways that were once unimaginable. Its ability to rapidly prototype, customize designs, and create complex objects is transforming industries, education, and healthcare. With each passing day, the technology becomes more accessible, affordable, and advanced, propelling us into a future where innovation knows no bounds. As we continue to embrace and refine 3D printing, we are witnessing a manufacturing revolution that will shape the world for generations to come.

Conclusion

In conclusion, 3D printing is revolutionizing manufacturing and prototyping in ways that were once unimaginable. Its ability to rapidly prototype, customize designs, and create complex objects is transforming industries, education, and healthcare. With each passing day, the technology becomes more accessible, affordable, and advanced, propelling us into a future where innovation knows no bounds. As we continue to embrace and refine 3D printing, we are witnessing a manufacturing revolution that will shape the world for generations to come.

As 3D printing continues to advance, its impact on manufacturing and prototyping becomes increasingly evident. This transformative technology empowers designers, engineers, and businesses to create innovative products with unprecedented levels of customization, complexity, and efficiency. From rapid prototyping to localized production and sustainable manufacturing practices, 3D printing is reshaping industries and unlocking new possibilities for the future. As we delve further into this digital manufacturing revolution, it is exciting to envision the limitless potential that 3D printing holds for innovation, creativity, and problem-solving in the years to come.

FAQ’s?

1. What is 3D printing?

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects by adding material layer by layer based on a digital design. It involves the use of a 3D printer that follows instructions from a computer-aided design (CAD) file to build the object.

2. How does 3D printing work?

3D printing typically involves the following steps:

- Creation of a 3D digital model using computer-aided design (CAD) software.

- Preparation of the model by slicing it into thin layers.

- Loading the 3D printer with the desired material (e.g., plastic filament or resin).

- The printer reads the sliced model and starts depositing or curing the material layer by layer to create the physical object.

- Once printing is complete, the object is removed from the printer, and any necessary post-processing (e.g., cleaning or sanding) is done.

3. What materials can be used in 3D printing?

3D printing can utilize a wide range of materials, including plastics (such as PLA or ABS), metals (like titanium or aluminum), ceramics, resins, and even biological materials like living cells for bioprinting applications. The choice of material depends on the specific requirements of the object being printed.

4. What are the applications of 3D printing?

3D printing has diverse applications across various industries, including:

- Prototyping and product development

- Customized manufacturing (e.g., personalized medical devices)

- Aerospace and automotive (e.g., lightweight and complex parts)

- Architecture and construction (e.g., building models and components)

- Healthcare (e.g., surgical models, prosthetics, and implants)

- Education (e.g., hands-on learning and creating visual aids)

- Art, fashion, and jewelry design

- Research and development

5. What are the advantages of 3D printing?

Some key advantages of 3D printing include:

- Rapid prototyping and reduced product development time

- Customization and personalization of products

- Complex geometries and intricate designs are achievable

- Reduced material waste compared to traditional manufacturing methods

- On-demand production and localized manufacturing

- Potential for cost savings, especially for small-scale production

- Accessible and democratized manufacturing for individuals and small businesses